Machine for hot stamping cone caps (applying decorative stripes on caps).

Machine is equipped with three hot stamping stations giving overall capacity of 4000 pcs/hour. Caps are fed and taken off by manipulators.

- possibility of switching off any stations;

- dimensions: 4000x900x1900 (mm);

- installed power: 2,8 kW.

Machine for assembling cosmetic cream jars consisting of 2 elements: inner bowl and outer bowl.

- elements for assembling are fed from injection moulder directly to the feeders;

- two-head machines of capacity ~4200pcs/hour;

- dimensions of base machine: 900x900x1800(mm);

- feeders length according to customer’s request;

- installed power: 0,5 kW.

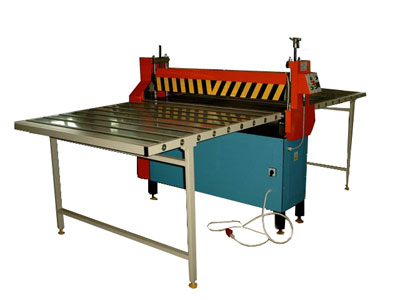

Machine for thermoforming foil and plastic plates.

We manufacture machines with different parameters according to customer’s request.

Automatic foil rewinder.

- rewinding speed – max 1540/min;

- dimensions: 2200x1200x1500(mm);

- installed power: 3kW.

Polski

Polski English

English Deutsch

Deutsch Pусский

Pусский